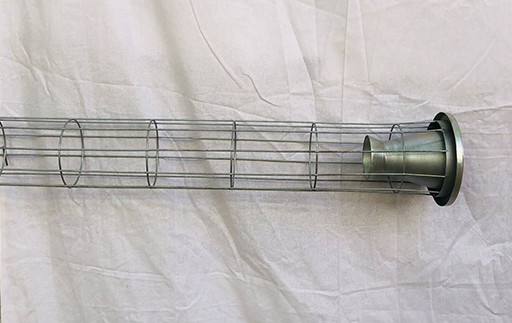

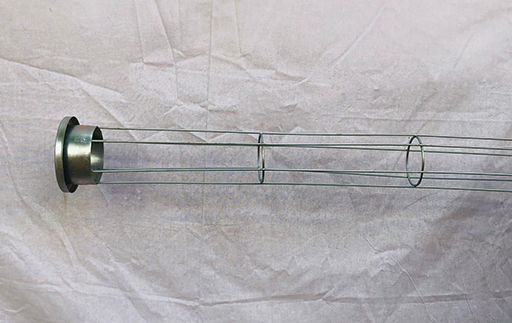

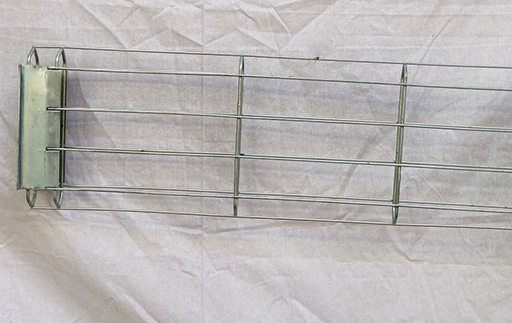

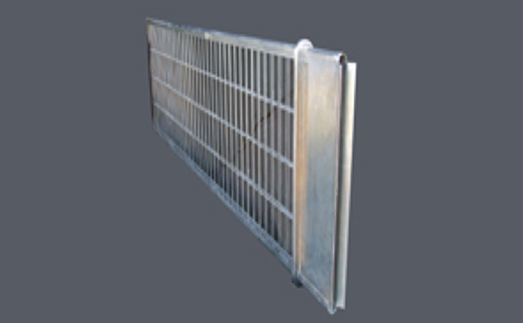

Filter Cage

We are the manufacturer of filter cages. We also supply different size, different surface treatment filter cages. If you have any inquiry, pls send mail to us or call us.

We can produce different type of filter cages. We use multi-point welding which is current equality and stabilization, has a high intension welding spot, so that surface is slick and non-burr Filter cage surface finishing. Galvanization/Spray-paint/Spray-plastic/Electrophores is paint/Spray painting anticorrosive dope.

We manufacture replacement cages for almost every pulse type collector on the market. We fabricate both carbon steel & galvanized filter cages, as well as epoxy coated in 8 to 24 vertical wire arrangements. The high speed welding line allows quick turn around on your order. We provide various top hardware to fit your top or bottom removal collectors. We manufacture a complete range of standard and non-standard cage design to suit. the customer’s requirement and all types of bags. Filter Cage configuration of circular, diamond, oval, flat and star shaped. Can be design and worked in a variety of metal-grades of mild. steel, stainless steel and specialist alloys.

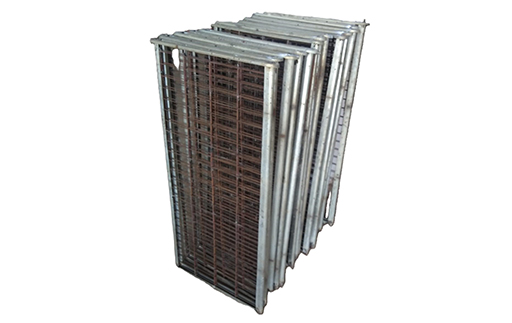

We manufacture our filter cages on CNC controlled welding machines to automate production process ensuring efficient & high quality products. The machine has multiple spot heads that increase our production rate and reduced our lead time. We have implemented rigorous QA procedure, which involve cage and component inspection through out all cages of production to the finished products. Cages are packed in steal/ wooden crates and safely dispatched.

Cage Manufacturing process;

* Wire straightening in wire straightening & cutting machine as per required length.

* Ring making in 3D CNC Wire bending machine as per required O D.

* But welding of Ring.

* Grinding of ring joint.

* As per design straight cut wire and ring spot welding on pneumatic spot welding machine.

* Welding of Top, Bottom and Venture on the Cage.

* Checking of joints with drop test and ensuring of straightness of Cage.

* Making fabricated racks to stack Cages properly.

* Loading the same in Vehicle for dispatch.